The Indian army with 1,129,900 active, 960,000 reserves and 158 aircraft stands guard at some of the most trying terrains owns the pride of world’s second largest armed force. After the independence, it has secured the Indian boundaries with Pakistan, China, and Bangladesh with topmost valor and efficiency. In order to continue to serve its primary goals i.e. to win a war, the army needs to keep on developing various capabilities, taking into account ever growing threat and sensitive operating environment. However the acquisition of such capabilities requires much more than just hardware.Besides the weapon system, it also requires associated maintenance infrastructure, together with an assured supply chain and complete infrastructure for training.These are required for sustaining the weapon system at the desired performance level for the entire life cycle and for continuously manning it by fully proficient crews, i.e. whole life management approach.

Themilitary supply chain has no parallel to any commercial supply chain both in terms of scope and deadly seriousness of the operations. The proper functioning of these support services is paramount for the soldiers at war. Even a small delay could result in unimaginable loss of lives and sometimes even war.

Historical Perspective:

Indian army Supply chain and logistics were inherited from British infrastructure along with an array of workshops, depots which were developed to serve in Second World War.After independence, defense public sector undertakings (DPSUs) and ordnance factories (OFs) were established for manufacturing defense equipment under license. They also undertook depot level repair and maintenance of the equipment manufactured by them. However, public sector work culture ensured that there were always time over runs and capacity constraints and the services had to set up elaborate infrastructure for maintenance up to depot level repair and overhaul(ROH) for not only the imported equipment but also xfor some of the equipment license manufacture that these DPSUs and OFs.

A typical Army Supply Chain structure:

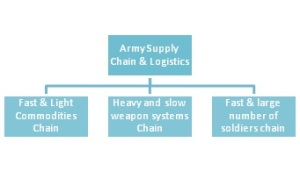

A military supply chain can be divided into three distinct chains. First, that is fast and moves light commodities like food, medicine and clothes- something like Wal-Mart. Second transports major weapon systems that require maintenance and repair over extended periods. Third chain is deployment chain in which army moves large number of soldiers in very short time and trying conditions. Unlike any commercial supply chain, army supply chain is known to have reverse and lateral flows. As and when army inculcates a weapon in its arsenal, it is solely responsible for its maintenance, up gradation and disposition, even as its user keeps on changing.

Fig 1: Army Supply Chain divisions

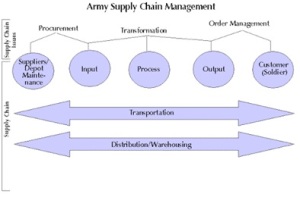

Fig 2: A Typical Army Supply chain process flow

Up gradation and modernization:

Over last two decades, Indian army has undergone a sea change of improvement by integration of computer technology and adoption of flexibility in structure. It is shedding unproductive practices and outsourcing them to private players in the market. The various maintenance and up gradation contracts with private players is such an initiative to lessen the burden of dud activities on army as well as bring efficient resource management. The advent of globalization has made its impact on the army operations as various bills which aims at promoting collaboration with foreign manufactures for development and research has given it a much needed advancement in supply chain and logistics activities.

However with all these efforts to evolve the army operations, there are some areas which still suffer from archaic guidelines, structure and hierarchy.

Future prospects & action plan

– Better infrastructure: As in most inhabited part of India, the infrastructure for army’s supply and logistics operations are either not in place or are in bad situation. Considering terrain diversity around Indian borders, it is paramount to develop reliable, safe and faster means of transporting commodities and services to area of impact.

– Separate supply chain and logistics command: Even though supply chain is so crucial for functioning of army, it is still treated as a sub division within forces. There is dire requirement to establish an integrated and separate division to utilize all the resources available with three defense forces.

– Increased focus on R&D: With the development of cutting edge technology in IT space and logistics, it is imperative for the army to invent new ways to maximize resource utilization and develop capabilities to respond to any potential call of support from the forces.

– Increase privatization & outsourcing: Most of the army’s support services are managed by bureaucratic division of the Indian government and hence they are plagued with inefficient and unsuitable processes and policies. In order to mitigate this disadvantage, army should aim to outsource its support services to Indian private operators on performance based contracts. This will remove the tardiness and stiffen the supply chain at par with world renowned Indian automobile industry.

– Increase mock supply chain and logistic drills: with all the proposed improvement, it is not worth if actual result are not achieved in critical time. Thus, frequent mock operation and testing is required to validate any shortcoming and loopholes which can later be improved. This would increase defense forces confidence on its supply chain and logistics and avoid any mishappening in course of war.

References

1. http://knowledge.wharton.upenn.edu

2. http://www.indiandefencereview.com/spotlights/revolution-in-military-logistics/3/